Two-Phase Flow in Pipelines and Heat Exchangers: A Comprehensive Guide

In the dynamic world of process engineering, the ability to manage fluid flow effectively is crucial for optimizing system performance and ensuring operational safety. One of the more intricate aspects of fluid dynamics is two-phase flow, a condition where both liquid and gas phases coexist within pipelines and heat exchangers. This phenomenon presents unique challenges that require careful consideration and expertise to address.

Accurately managing two-phase flow is not just about maintaining system efficiency; it’s also about preventing potential issues that could arise from improper handling, such as increased wear and tear, pressure surges, and safety hazards. For industries dealing with complex fluid systems, understanding and optimizing two-phase flow is essential for achieving reliable and cost-effective operations.

What is a Two-Phase Flow?

Two-phase flow involves the simultaneous movement of two distinct phases, commonly a liquid and a gas, within a conduit or heat exchanger. This flow regime is prevalent in various industries, including oil and gas, chemical processing, and power generation. Two-phase flow can appear in different patterns and can be influenced by factors such as fluid properties, flow rates, and system design.

Significance of Effective Two-Phase Flow Management:

Proper management of two-phase flow is vital for several reasons:

- Optimized Performance: Efficient handling of two-phase flow ensures that pipelines and heat exchangers operate at their designed capacity. This optimization is crucial for maintaining high performance and avoiding disruptions in the process.

- Reduced Corrosion and Erosion: Improper flow management can lead to increased wear and tear on equipment, such as corrosion and erosion in pipelines and heat exchangers. Addressing these issues proactively extends the lifespan of the equipment and reduces maintenance costs.

- Enhanced Safety: Two-phase flow can lead to pressure surges and other hazardous conditions if not properly managed. Effective flow management helps mitigate these risks, ensuring safe operation and preventing potential accidents.

- Cost Efficiency: By effectively managing two-phase flow, businesses can reduce energy consumption and operational costs, leading to significant financial savings.

Types of Two-Phase Flow Patterns in Pipelines:

Two-phase flow in pipelines can exhibit several distinct patterns, each with unique characteristics:

- Slug Flow: In slug flow, gas and liquid phases alternate in distinct slugs or pockets. This pattern can cause pressure fluctuations and vibrations, potentially leading to pipe vibrations and damage. It is often seen in vertical and inclined pipes.

- Bubbly Flow: Bubbly flow is the dispersion of gas bubbles throughout the liquid phase. The bubbles rise through the liquid, creating a relatively stable flow pattern. This type of flow is generally less troublesome than slug flow, but it still requires careful management to ensure efficiency.

- Annular Flow: In annular flow, a core of gas flows through the center of the pipe while a thin film of liquid adheres to the pipe walls. This flow pattern is common in high-velocity systems and can create high shear forces that impact the performance and integrity of the pipeline.

Understanding these flow patterns is crucial for designing pipelines that can handle specific flow controls and minimize issues related to flow instability and equipment wear.

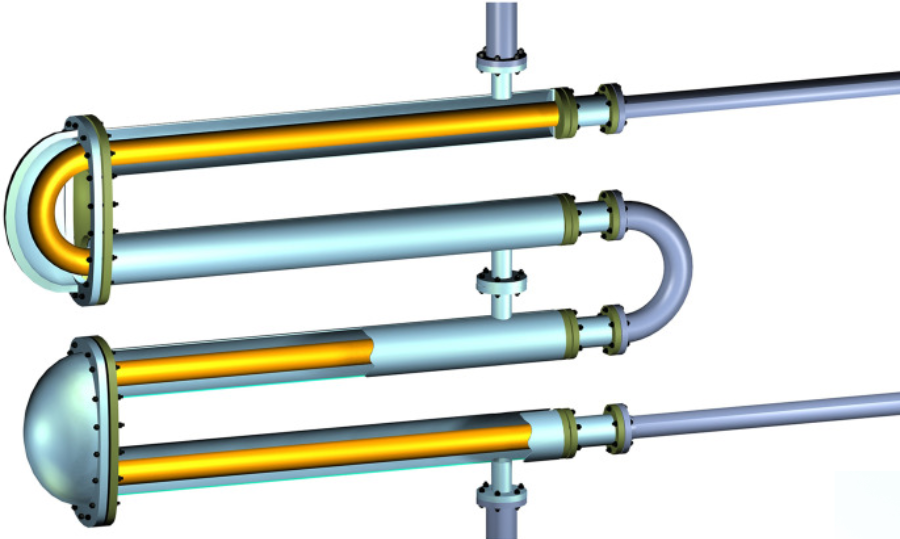

Two-Phase Flow in Heat Exchangers:

Heat exchangers are essential for transferring heat between two fluids in various industrial processes. When dealing with two-phase flow, heat exchangers face unique challenges:

- Heat Transfer Efficiency: Two-phase flow significantly affects the heat transfer efficiency in heat exchangers. During phase changes, such as boiling or condensation, the heat transfer properties can vary, impacting the exchanger’s overall performance.

- Pressure Drops: The interaction between the liquid and gas phases can lead to increased pressure drops across the heat exchanger. Higher pressure drops require additional energy to maintain flow, impacting operational efficiency and increasing costs.

- Design Considerations: Engineers need to design heat exchangers to handle two-phase flow conditions carefully. This involves choosing suitable materials, ensuring uniform flow distribution, and optimizing heat transfer surfaces.

Strategies for Managing Two-Phase Flow:

To effectively manage two-phase flow in pipelines and heat exchangers, several strategies can be employed:

- Flow Pattern Analysis: Conducting a thorough analysis of the expected flow patterns helps in designing systems that can handle specific flow regimes. Advanced computational models and simulations can predict flow behavior and aid in optimizing design.

- Advanced Instrumentation: Implementing state-of-the-art sensors and instrumentation allows for real-time monitoring of flow conditions. This technology enables timely adjustments to maintain optimal performance and prevent issues.

- System Design Optimization: Designing pipelines and heat exchangers with two-phase flow characteristics in mind helps mitigate problems such as pressure drops and erosion. Key considerations include pipe diameter, material selection, and heat exchanger configuration.

- Regular Maintenance and Inspection: Regular maintenance and inspection are essential for identifying and managing issues related to two-phase flow. Proactive maintenance helps control costly downtime and extends the equipment’s lifespan.

How Converge Engineering Pvt. Ltd. Can Help:

At Converge Engineering Pvt. Ltd., we specialize in providing cutting-edge process engineering solutions tailored to the unique challenges of managing two-phase flow. Our expertise ensures that your pipelines and heat exchangers operate efficiently and reliably. Our services include:

- Customized Design Solutions: We offer bespoke design solutions for pipelines and heat exchangers, optimizing them for two-phase flow conditions to enhance performance and reduce operational issues.

- Advanced Modeling and Simulation: Utilizing advanced simulation tools, we model two-phase flow scenarios to predict performance and refine system design, ensuring optimal efficiency.

- Real-Time Monitoring and Control: We implement sophisticated instrumentation for real-time monitoring and control of two-phase flow, allowing for prompt adjustments and maintaining peak performance.

- Comprehensive Maintenance and Support: Our team provides ongoing maintenance and support, addressing any issues related to two-phase flow and helping you avoid costly repairs and downtime.

Contact Us

If you’re looking for expert solutions to manage two-phase flow in your pipelines and heat exchangers, Converge Engineering Pvt. Ltd. is here to assist you. As a leading Process Engineering Consultant in India, we specialize in providing advanced and specialized solutions for managing two-phase flow in pipelines and heat exchangers. Our team of experienced engineers and experts can work closely with you to understand your specific needs and challenges, and then develop tailored solutions to optimize the performance and efficiency of your systems. Whether you are dealing with complex flow dynamics, heat transfer issues, or any other related challenges, we are here to help. Contact us today to initiate a detailed discussion about your requirements and explore how our expertise can benefit your operations.